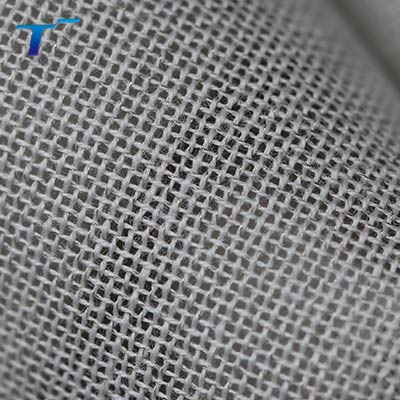

Thermal Conductive Fabric (Model No.: TF-SSFML1) is a high-performance stainless steel fiber blend fabric that combines the flexibility of textile fabric with excellent thermal and electrical conductivity. It can withstand working temperatures of around 600°C and is environmentally friendly, flame retardant, anti-cutting, and easy to cut and process. With its superior heat transfer, shielding, and high-temperature resistance properties, it is ideal for applications in smart textiles, wearable devices, industrial protection, and electromagnetic shielding.

Thermal Conductive Fabric

Specification

Technical Data:

Conductivity: ≤0.5Ω/cm.

Shielding effectiveness: 50~80dB

Operating temperature range: 500 - 600 degrees Celsius(°C)

Melting Point: 1300 degrees Celsius(°C)

| Model No. | TF-SSF601 | TF–SSF602 | TF–SSF603 | TF–SSF604 |

| Width | 100cm, 120cm, 150cm, 160cm | |||

| Fiber Diameter (µm) | 8 | 8 | 8,12 | 8,12 |

| Yarn Count (Nm) | 16 Nm/2 | 12 Nm/2 | 8.6 Nm/2 | 6 Nm/2 |

| Texture | Plain, Twill | |||

| Thickness (mm) | 0.5±0.05 | 0.65±0.05 | 0.68±0.05 | 0.75±0.05 |

| Weight (g/m2) | 580±20 | 650±25 | 800±25 | 980±25 |

| Air Permeability (mm/s) | 1200±100 | 1180±100 | 1100±100 | 950±100 |

Working Principle of Thermal Conductive Fabric

Made from stainless steel fiber blend fabric that efficiently conducts heat.

Metal fibers form continuous pathways for rapid heat transfer and dissipation.

Helps prevent hotspots and maintain stable temperatures across the surface.

Retains flexibility, breathability, and softness like traditional textiles.

Ideal for smart textiles, wearable devices, industrial protection, and heat management applications.

Why Choose Us — Texcraf

Professional Expertise: Texcraf specializes in functional yarns and fabrics, focusing on shielding, conductivity, high-temperature resistance, and flame retardancy.

Advanced Production Facilities: Equipped with silver-plating, textile, and sewing workshops, ensuring high-quality and consistent production.

Strong R&D Capability: A dedicated research and development team led by experienced textile engineers continuously innovates to meet diverse market needs.

Customization Service: Offers tailor-made solutions for thermal conductive and shielding fabrics according to specific customer requirements.

Comprehensive Product Range: Covers silver-plated fabrics, stainless steel blended textiles, aramid conductive fabrics, and other high-performance materials.

Efficient Global Service: An independent international trade team provides professional, fast, and reliable procurement support for global clients.

Quality & Innovation: Texcraf prioritizes product quality, continuous improvement, and customer satisfaction, ensuring long-term partnership value.

Thermal conductive fabric, also known as heat-dissipating fabric, is designed to efficiently transfer heat away from its source. It is commonly used in various applications where heat management is crucial. Here are some examples of its applications:

Electronics: Thermal conductive fabric is often used in electronic devices to dissipate heat generated by components such as processors, graphics cards, and power modules. It can be integrated into heat sinks, thermal pads, or thermal interface materials to improve heat transfer and prevent overheating, which can lead to performance degradation or component failure.

Apparel: In some specialized garments, thermal conductive fabric can be used to enhance temperature regulation. For example, it may be incorporated into sportswear or outerwear to wick away excess heat generated during physical activities and provide better comfort.

Insulation: Thermal conductive fabric can be used as a part of insulation systems to regulate temperature. It can assist in distributing heat evenly or redirecting it away from specific areas. This application is commonly seen in aerospace, automotive, and building industries.

Medical applications: Thermal conductive fabric can be utilized in medical devices or garments where localized temperature control is necessary. For instance, it may be incorporated into heating or cooling pads to provide therapeutic benefits for patients.

Energy systems: In renewable energy systems, such as solar panels or batteries, thermal conductive fabric can help manage heat generated during operation. By efficiently dissipating heat, it can enhance the performance, longevity, and safety of these systems.

Industrial applications: Thermal conductive fabric can find uses in industrial settings where heat management is vital. It may be employed in equipment or machinery to dissipate excess heat, improving efficiency and preventing damage due to overheating.

High Thermal Conductivity: Thermal conductive fabrics are engineered to have high thermal conductivity, meaning they can efficiently transfer heat from one point to another. This property allows them to quickly and effectively dissipate heat away from the heat source.

Low Thermal Resistance: These fabrics have a low thermal resistance, which means they offer minimal obstruction to the flow of heat. Low thermal resistance ensures that heat can easily pass through the fabric without significant barriers, enabling efficient heat transfer.

Lightweight and Flexible: Thermal conductive fabrics are typically lightweight and flexible, allowing for easy integration into various applications. Their flexibility enables them to conform to different shapes and contours, making them suitable for use in complex or curved surfaces.

Durable and Long-lasting: Thermal conductive fabrics are designed to withstand repeated use and maintain their thermal properties over time. They are often engineered with durable materials and coatings to ensure longevity and reliability.

Electrical Insulation: In many applications, it is essential for thermal conductive fabrics to provide electrical insulation. This feature ensures that the fabric does not conduct electricity, preventing any electrical hazards or short circuits when used in close proximity to electrical components.

Breathability and Moisture Management: In certain applications, such as sportswear or medical garments, thermal conductive fabrics may incorporate moisture-wicking and breathability properties. These features help to enhance comfort by allowing moisture and sweat to evaporate, keeping the wearer dry and cool.

Compatibility with Various Environments: Thermal conductive fabrics are often designed to withstand a range of environmental conditions, including high temperatures, humidity, and exposure to chemicals. This allows them to be used in diverse settings and industries.