The rapid expansion of Internet of Things (IoT) devices and advancements in medical electronics have revolutionized industries—but they also bring a hidden challenge: electromagnetic interference (EMI). As devices become more interconnected, the risk of signal disruption, data corruption, and even health concerns from prolonged EMF exposure grows.

To combat these issues, leading manufacturers are turning to EMF shielding fabrics—a cutting-edge solution that ensures device reliability, regulatory compliance, and user safety. Texcraf Protection, a pioneer in high-performance EMF shielding materials, provides industry-leading fabrics that meet the stringent demands of IoT and medical applications.

In this article, we explore:

The growing need for EMF shielding in IoT and medical devices

How EMF fabrics enhance performance and safety

Key industry applications and case studies

Why Texcraf Protection is the preferred partner for manufacturers

The IoT market is projected to exceed $1.5 trillion by 2030, with billions of interconnected devices—from smart home sensors to industrial automation systems. However, this growth comes with challenges:

Signal interference from crowded wireless spectrums (Wi-Fi, 5G, Bluetooth)

Data security risks due to EMI-induced malfunctions

Regulatory pressures (FCC, CE, IEC standards) requiring EMI mitigation

EMF fabrics act as a Faraday cage, blocking unwanted interference while maintaining critical signal integrity.

Medical electronics—such as MRI machines, pacemakers, and wearable health monitors—must operate flawlessly. EMI can cause:

False readings in diagnostic equipment

Malfunctions in life-saving implants

Data breaches in wireless medical devices

Regulatory bodies like the FDA and EU MDR now enforce strict EMI shielding requirements, pushing manufacturers to adopt high-performance EMF fabrics.

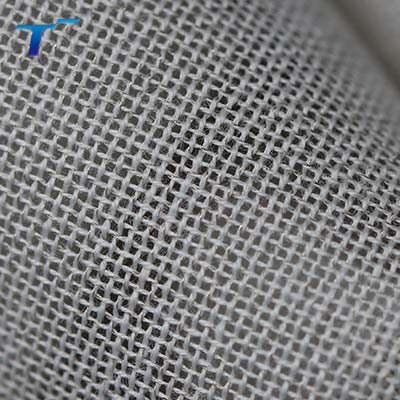

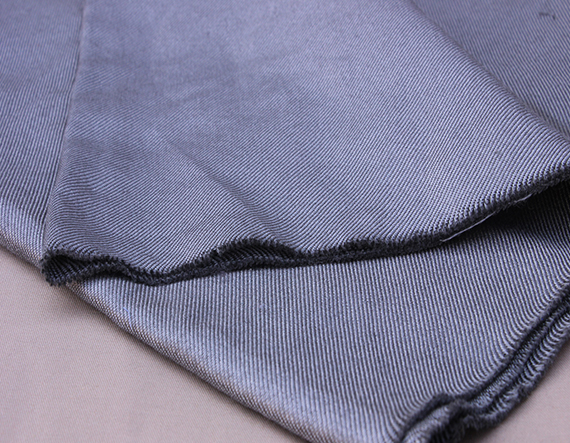

Texcraf Protection’s silver-plated and copper-nickel fabrics offer:

Up to 80 dB attenuation (blocking 99.99% of interference)

Flexible, lightweight integration into device casings and internal components

Durability (washable, bend-resistant, and corrosion-proof)

Manufacturers must meet:

FCC Part 15 (US) for electronic emissions

IEC 60601-1-2 (Medical EMI Standards)

EU EMC Directive

Texcraf’s fabrics are pre-certified, reducing time-to-market for compliant devices.

EMI can be exploited for data theft or signal jamming. EMF shielding:

Prevents side-channel attacks on smart devices

Secures wireless transmissions in industrial IoT

Protects against intentional EMI sabotage (critical for defense and infrastructure)

MRI rooms use EMF fabrics to contain interference.

Wearable health monitors maintain accuracy despite external EMF noise.

Implantable devices (e.g., pacemakers) avoid disruptions from smartphones and other electronics.

A leading smart thermostat manufacturer faced signal dropout issues in high-EMF urban areas. By integrating Texcraf’s silver-nylon fabric into device housings, they achieved:

30% improvement in signal stability

FCC compliance without redesigns

A wearable ECG developer struggled with false readings near Wi-Fi routers. After adopting copper-knitted shielding fabric, their device:

Passed IEC 60601-1-2 testing

Reduced EMI-related errors by 95%

5G-enabled devices (shielding mmWave interference)

Electric vehicle (EV) sensors (preventing EMI from high-power systems)

Robotic surgery tools (ensuring precision in high-EMF environments)

Hybrid metal fabrics (silver, copper, stainless steel) for multi-frequency shielding

Custom weaves and coatings for specific device requirements

EMI testing & certification assistance

Prototype development for seamless integration

Scalable production (from small batches to mass manufacturing)

Texcraf’s fabrics are used by:

Top 5 IoT device makers

Medical OEMs compliant with FDA/EU MDR

Aerospace and defense contractors

As IoT and medical devices grow more sophisticated, EMI shielding is no longer optional—it’s a competitive necessity. Manufacturers that adopt high-performance EMF fabrics gain:

Reliable, interference-free operation

Faster regulatory approvals

Enhanced cybersecurity and patient safety

Texcraf Protection delivers scientifically validated, customizable shielding solutions trusted by industry leaders.

Copyright © Xiongxian texcraf Technology Co., LTD. All Rights Reserved | Sitemap