Analysis of the Impact of Rising International Silver Prices on Silver Fiber Electromagnetic Shielding Products.

I. Manufacturing Principle and Structure of Silver Fiber

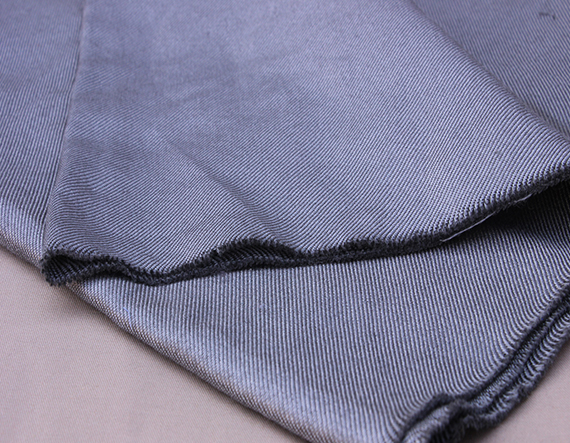

Silver fiber is produced by bonding pure silver uniformly onto a nylon base material through special processes, forming a nano-level metal silver coating.

Silver Content Proportion: Typically ranges from 12% to 20%, depending on the base material's yarn weave and density.

Yarn Types: Classified into short fibers and long filaments, which can be blended or twisted with natural fibers (e.g., cotton/hemp) or chemical fibers (e.g., polyester, wool) to create multifunctional yarns.

Electromagnetic Shielding Mechanism: After being woven into fabric, the silver layer forms a网状metal structure that achieves shielding by reflecting and absorbing electromagnetic waves.

II. Impact of Rising International Silver Prices on Silver Fiber Products

Cost Transmission Mechanism

Direct Impact of Silver Price Fluctuations: In December 2025, London silver prices surged to $69.450 per ounce during trading, with annual gains exceeding 130%, directly driving up the cost of silver fiber yarns and fabrics.

Cost Sensitivity: For every 1% increase in silver prices, the cost of silver fiber yarns rises by approximately 0.5%-1%. Silver fiber fabric prices are typically quoted based on daily international silver prices.

EMF Silver Fiber Fabric Price Increases: Due to technological optimization (e.g., reduced silver usage) and market competition, fabric price increases usually lag behind silver price hikes.

Technological Upgrades to Mitigate Cost Pressures

Widespread Implanted Silver Coating Technology: Integrates silver ions into chemical fiber substrates to enhance stability and reduce silver consumption.

TISSU Physical High-Tech Technology: Permanently bonds pure silver to nylon surfaces, preventing silver loss.

Sputtering Technology: Incorporates nano-silver into yarns, minimizing silver waste in traditional processes.

Blend Optimization: Adjusts the ratio of silver fiber to metal fibers and polyester, lowering silver content.

Market Effects and Alternative Solutions

Downstream Industry Cost Pressures: Rising silver prices may increase costs for electromagnetic shielding garments and electronic protective equipment, but silver fiber's antibacterial and anti-radiation properties remain irreplaceable.

Alternative Material Options:

Metal Fiber Blends: Lower cost, with shielding values exceeding 30dB, suitable for daily protection.

Copper-Nickel Metal Fabrics: Shielding values of 45-70dB, but less soft, ideal for industrial shielding and conductive components, widely used in electronics.

Consumer Purchase Recommendations:

Household and Personal Use: Prioritize silver fiber electromagnetic shielding fabrics for balanced protection and comfort.

Electronics Professionals: Metal fiber blends offer higher cost-effectiveness.

Budget-Conscious Consumers: Opt for metal fiber blend fabrics (shielding values >30dB).

III. Core Functions of Silver Fiber Fabrics

Electromagnetic Shielding: Shielding values reach 57-65dB, effectively blocking electromagnetic waves from phones, computers, etc.

Anti-Static: Silver's conductivity quickly dissipates static electricity generated by friction, enhancing wearing comfort.

Odor Removal and Antibacterial Properties: Silver ions adsorb and decompose odor molecules while disrupting bacterial physiological processes, achieving strong deodorization and antibacterial effects.

Temperature Regulation: Provides warmth in winter and coolness in summer, with excellent breathability, suitable for贴身wear.

Washability: Can be machine-washed, ideal for long-term use.

IV. Industry Strategies and Long-Term Trends

Technological Iteration: Reduces silver loss through sputtering technology and nano-silver coating optimization, balancing cost and performance.

Market Strategies: Companies may shift toward metal fiber blends or develop new composite materials, but silver fiber demand remains stable in medical and military sectors.

Long-Term Outlook: While silver price volatility is influenced by global supply-demand dynamics, silver fiber's unique properties ensure its competitiveness in high-end protective markets.

V. Conclusion

Rising international silver prices directly increase the cost of silver fiber yarns and fabrics, but technological upgrades and material optimization partially offset these pressures. Silver fiber's core advantages in electromagnetic shielding and antibacterial properties remain unmatched, while metal fiber blends provide alternatives for budget-limited consumers. In the future, silver fiber products will continue to dominate high-end protective markets as technology evolves and demand diversifies.

Copyright © Xiongxian texcraf Technology Co., LTD. All Rights Reserved | Sitemap