When selecting electromagnetic shielding solutions for your industrial applications, you face a critical decision: should you use modern EMF fabrics or stick with traditional shielding materials? This comprehensive comparison provides the technical insights you need to make an informed purchasing decision based on your specific requirements.

Traditional shielding materials have been the industry standard for decades, offering reliable protection in demanding environments. The most common options include:

Metal sheets and enclosures (aluminum, copper, steel)

Conductive coatings and paints (silver, nickel, or carbon-based)

Metal foils and tapes (copper or aluminum)

These materials deliver exceptional shielding effectiveness, typically ranging from 60dB to 120dB across all frequencies. Their rigid structure provides consistent performance in harsh conditions, making them ideal for:

Permanent installations in industrial facilities

High-temperature environments

Applications requiring maximum shielding effectiveness

However, traditional materials present challenges in weight, installation complexity, and design flexibility that may impact your project's cost and timeline.

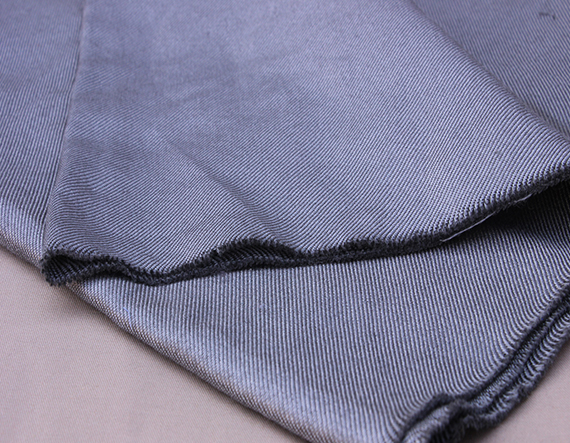

Modern EMF shielding fabrics combine conductive materials with textile substrates to create versatile shielding solutions. The most common types include:

Silver-coated fabrics (highest conductivity)

Copper/nickel blended textiles

Carbon-infused conductive fabrics

These materials typically offer 30-80dB of shielding effectiveness, with key advantages:

Lightweight construction (500g/m² or less)

Flexibility and conformability

Ease of installation and modification

Breathability for wearable applications

While EMF fabrics can't match the absolute shielding performance of solid metal enclosures, they solve critical challenges in applications where traditional materials prove impractical.

| Parameter | EMF Fabrics | Traditional Materials |

|---|---|---|

| Shielding Effectiveness | 30-80 dB | 60-120 dB |

| Weight | <500 g/m² | >2000 g/m² |

| Frequency Range | Best below 6 GHz | Full spectrum |

| Installation Complexity | Low (cut/sew) | High (welding/bolting) |

| Durability | Moderate (wear concerns) | Excellent |

| Cost per m² | $50-$300 | $20-$150 (material only) |

| Customization | Easy | Difficult |

Wearable radiation protection for technicians

Temporary shielding solutions in field work

Complex geometries requiring conformability

Lightweight applications where mass is critical

RF-secure enclosures needing ventilation

Permanent EMI shielding rooms

High-power industrial equipment

Military/aerospace applications

Environments requiring chemical/heat resistance

Maximum shielding effectiveness requirements

While traditional materials often appear cheaper initially, consider these factors in your purchasing decision:

Installation Costs:

EMF fabrics require minimal labor

Metal enclosures need skilled tradespeople

Maintenance Requirements:

Fabrics may need periodic replacement

Metal solutions typically last decades

Design Flexibility:

Fabric modifications are simple

Metal changes require cutting/welding

Transport/Handling:

Fabrics reduce shipping weight

Metal adds substantial mass

Innovative manufacturers like TEXCRAF now offer advanced hybrid solutions that combine the benefits of both approaches:

Metal-coated textiles for improved durability

Reinforced fabric composites with enhanced shielding

Modular systems allowing flexible configurations

Before selecting your shielding solution, answer these critical questions:

What frequency range requires protection?

What shielding effectiveness (dB) is required?

Are weight and flexibility important factors?

What environmental conditions will the material face?

What is your total budget including installation?

Are there any industry-specific compliance requirements?

When evaluating suppliers for your shielding materials, prioritize those who:

Provide independent test data for their products

Offer technical consultation for your specific application

Can supply material samples for your evaluation

Have experience in your industry sector

Offer customization options when needed

Companies like TEXCRAF specialize in both traditional and fabric-based shielding solutions, making them valuable partners for comparing options side-by-side.

The choice between EMF fabrics and traditional shielding materials depends entirely on your application requirements. For maximum shielding in fixed installations, traditional metals remain the gold standard. For flexible, lightweight, or temporary solutions, modern EMF fabrics offer compelling advantages.

As hybrid technologies continue to evolve, the line between these categories will blur, offering industrial buyers even more options to address their specific EMI challenges. By carefully evaluating your needs against the technical specifications of available solutions, you can select the most effective and cost-efficient shielding approach for your operation.

Copyright © Xiongxian texcraf Technology Co., LTD. All Rights Reserved | Sitemap