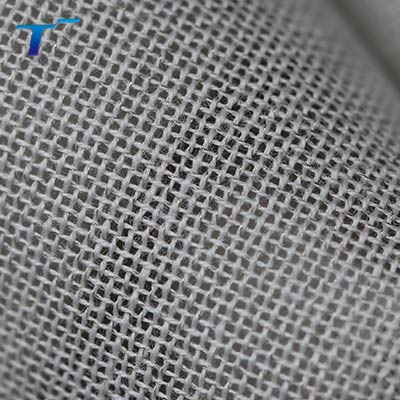

Stainless Steel Fibre Knitted Sleeving

Stainless steel fibre knitted sleeving are made by knitting fine stainless steel yarns into a tubular construction so as to make them particularly elastic and, therefore, the ideal solution for covering purposes.

The stainless steel fibre makes the sleeve particularly resistant to high temperatures and thermal shock associated with molten and quenching phases of glass production.

The incredible fineness of the fibres ensures a super soft scratch resistant medium that prevents any marks or scratches forming on the glass surface.

The knitted elastic structure facilitates maintenance work as they are easy to apply and remove from the roller.

The Sleeving wall can be modified to suit the specific medium being carried. For example, a thicker wall might be preferential for better shock absorption in case of glass impact. Thinner walls may be preferred in other applications where roller speed is more important than their ability to cushion.

Knitted constructions allow for a high degree of elasticity meaning one ‘nominal’ diameter might cover a large range of diameters due to range of minimum and maximum expansion.

Rated to 650°C in optimum conditions.

They can also be knitted from steel yarns that have been blended with para aramid fibre leading to a reduction in cost.

Heat-resistant binding fixture, conductive transmission, heat generation, mould covering materials for automotive glass molding, high temperature resistant buffer materials for glass industry, glassware molding materials, temperature resistant products operated in high temperature environments, high temperature resistant conveyor belts, permanent shielding and conductive materials, anti-static brush, various anti-static products , widely used in textile, printing, copier, electroplating, compounding, coating, printing and dyeing, papermaking, plastics, packaging, rubber and other industries.

100% Stainless Steel Fiber Knitted Sleeve is knitted from 100% 316L stainless steel fiber yarn. It has the advantages of high temperature resistance, smooth surface, softness, high air permeability, as well as good electrical conductivity, low resistance, good thermal conductivity, cut resistance, anti-corrosion and wear resistance.